ULVAC爱发科 电弧等离子法纳米粒子形成装置 APD-S

ULVAC爱发科 电弧等离子法纳米粒子形成装置 APD-SULVAC爱发科 电弧等离子法纳米粒子形成装置 APD-S是利用脉冲真空电弧放电的新型纳米粒子形成装置。脉冲真空电弧蒸发是以简单的工艺产生金属离子,形成极薄膜和纳米粒子的唯一方法。在微粒子的形成等方面,可以获得其他蒸发法不能获得的效果。特点APD-P可对用纳米粒子APD-S可控制从nm级的膜厚到μm级的膜厚的脉冲数,可以容易地控制膜

- 型号: APD-S

ULVAC爱发科 电弧等离子法纳米粒子形成装置 APD-SULVAC爱发科 电弧等离子法纳米粒子形成装置 APD-S是利用脉冲真空电弧放电的新型纳米粒子形成装置。脉冲真空电弧蒸发是以简单的工艺产生金属离子,形成极薄膜和纳米粒子的唯一方法。在微粒子的形成等方面,可以获得其他蒸发法不能获得的效果。特点APD-P可对用纳米粒子APD-S可控制从nm级的膜厚到μm级的膜厚的脉冲数,可以容易地控制膜

ULVAC爱发科 电弧等离子法纳米粒子形成装置 APD-S

ULVAC爱发科 电弧等离子法纳米粒子形成装置 APD-S

APD-P

可对用纳米粒子

APD-S

可控制从nm级的膜厚到μm级的膜厚的脉冲数,可以容易地控制膜厚。

APD-P(用于在粉末上加载纳米颗粒)

使用纳米粒的燃料电池催化剂 排气催化剂 光触媒

VOC分散催化剂 碳纳米管催化剂 等离子

APD-S(基板成膜用)

金属薄膜(磁性 等离子 保护膜)

| Model | APD-S | APD-P |

|---|---|---|

| Sample size | Substrate Φ 2 inch | Powder Vessel size(inside dimension) Φ 95mm × H 30mm with stirring mechanism |

| Standard deposition numbers | 1 | 1 |

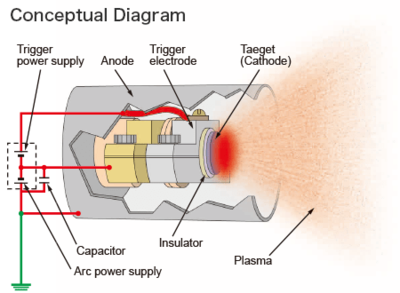

After chamber evacuation, a trigger induces an arc discharge on the surface of target rod. Then highly ionized metal plasma is generated from the target rod without any discharge gases, and deposits on the substrate to form various thin films and nano-particles.

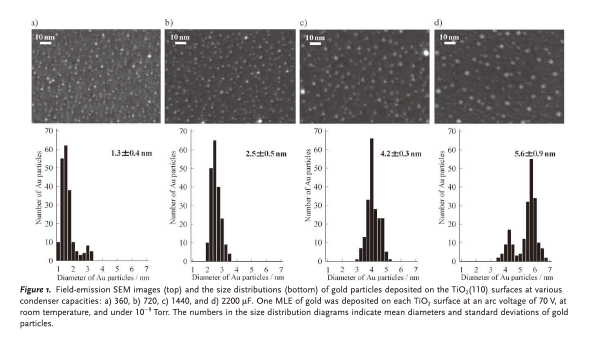

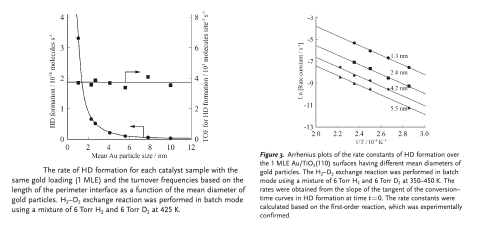

The system can select nano-particle diameter within the range of approx. 1.5nm to 6nm by changing condenser capacity.

The system can make any material plasmatic in case they are electrically-conductive materials(target).

*Specific resistance for target is 0.01Ωcm or less

The system can readily generate oxide and nitride by changing atmosphere.

Also, when graphite is discharged in H2 gas, it generates UNCD(Ultrananocrystalline diamond).

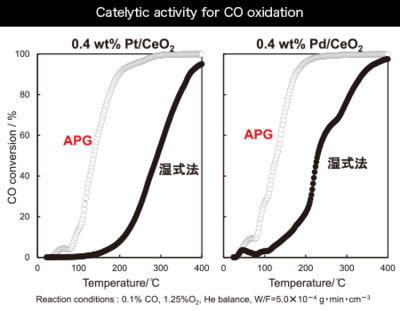

The nano-particles supported by the system shows active catalytic effects as compared with wet process.

Model APD-P supports nano-particles to powders.

Model APD-S supports nano-particles to 2-inch substrate.

*The above-mentioned 1, 3 and 4 depend on literatures.

Pt and Pd catalysts supported to CeO2 with Arc-Plasma method show higher catalytic activity for CO oxidation as compared with catalysts with conventional wet process.

Quoted literatures: “Ministry of Education, element strategic project achievement” by Professor Machida at Kumamoto University

TEM image in which the system supports Pt to carbon powders

Quoted literatures: Article published by Mr. Tadahiro Fujitani at Research Institute for Innovation in Sustainable

Chemistry in National Institute of Advanced Industrial Science and Technology

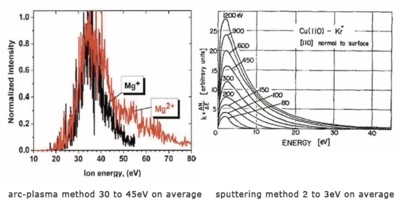

The difference in energies largely contributes to the generation and function of nano-particles.

(The vertical axis is no unit of quantity required due to relative values.)

Quoted literatures: Arc-plasma J. Appl. Phys. 101(2007)043304 SputterJ. Appl. Phys. 35(1964)1819